Custom tube bending

Whether you are looking for a custom CNC millingpart for a brand or are just looking for a professional CNC milling supplier, AFI is your first choice.

定制数控弯管折弯加工

公司拥有cnc机加工设备100+,专注于定制CNC 车削加工,利用先进的数控技术,将各类材料加工成精密的车削零部件。

设备

这是测试文本,单击 “编辑” 按钮更改此文本。

加工

这是测试文本,单击 “编辑” 按钮更改此文本。

零件

这是测试文本,单击 “编辑” 按钮更改此文本。

检测

这是测试文本,单击 “编辑” 按钮更改此文本。

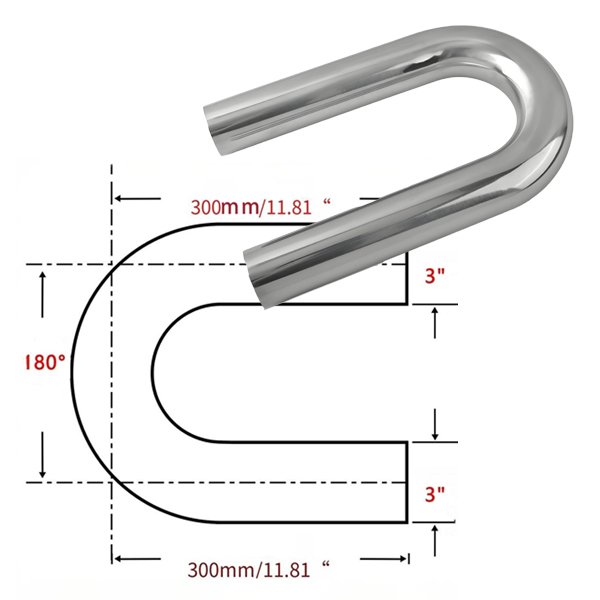

订制的金属弯管服务

弯管服务可为各种应用提供无与伦比的精度和质量。该服务是汽车、航空航天和建筑行业的理想选择,可提供定制的弯管解决方案以满足特定项目要求。凭借先进的技术和熟练的工艺,弯管每次都能确保弯管准确、耐用且完美。该工艺非常适合小批量和大批量生产,使其成为原型或批量生产的多功能选择。通过专业的弯管服务,您可以体验到缩短生产时间、提高成本效益和卓越产品性能的好处。使用经久耐用且按照精确规格制作的组件来提升您的项目。

精密数控折弯服务

精密铣削加工通过先进的铣削设备和专业的刀具,对工件进行精细切削。能实现复杂形状的加工,尺寸精度高,表面质量好。广泛应用于航空航天、电子等领域,为高质量产品的制造提供有力保障.

弯管原型开发

利用我们的快速原型 CNC 铣削服务加速您的产品开发。我们的原型制作功能非常适合设计师和工程师,可让您快速测试和改进设计,缩短上市时间并确保最终产品符合所有规格。

定制折弯

定制精密 CNC 铣前削件,是根据特定需求精心打造的关键部件。采用先进的 CNC 加工技术,确保高精度与高质量。每一个细节都经过严格把控,尺寸精准,表面光滑。它能满足复杂工程的严格要求,为各类设备提供可靠支持,提升整体性能。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

定制弯管的材料

公司拥有cnc机加工设备100+,专注于定制CNC 车削加工,利用先进的数控技术,将各类材料加工成精密的车削零部件。

Aluminum is light but strong, with excellent machinability and corrosion resistance. Ideal for aerospace and automotive components, including

- 6061

- 2024

- 5083

- 6082

- 7075-t6

- 6061-T6

- 5052

- 6063

- 7075

- AFC12(A380)

Copper is known for its excellent conductivity and thermal properties, making it ideal for electrical components and heat exchangers.

- C101(T2)

- C103(T1)

- C103(TU2)

- C110(TU0)

- Beryllium copper

Steel is an alloy with high tensile strength and high durability and is commonly used in the construction and automotive industries due to its robustness.

- 1018,

- 1020,

- 1025,

- 1045,

- 1215,

- 4130,

- 4140,

- 4340,

- 5140,

- A36

- Die steel

- Alloy steel

- SPCC

- Chisel tool steel

- Spring steel

- steel

- High speed steel

- Cold rolled steel

Alloy hardness, good heat resistance, corrosion resistance, etc., including

- steel alloy

- aluminum alloy

- inc alloy

Stainless steel is known for its corrosion resistance, making it the first choice for medical equipment and food processing equipment.

- SUS201

- SUS 304

- SUS316L

- SUS440C

- AISI 304

- SUS630/17-4PH

- SUS303

- SUS316

- SUS420

- SUS430

- SUS431

定制弯管的表面处理

金属弯管的表面处理是一个关键步骤,它直接影响到弯管的防腐层使用寿命、涂层质量以及施工条件的好坏。正确的表面处理能够确保防腐层与金属表面有良好的粘结性能,从而保护金属免受外界介质的腐蚀。以下是金属弯管表面处理的主要步骤和方法:

Anodizing: refers to the process of placing the metal in an appropriate electrolyte and forming an oxide film on the metal surface through the action of external current. This layer of oxide film has the characteristics of high hardness, high corrosion resistance and high insulation, which can protect the metal surface from environmental erosion, and improve the wear resistance and corrosion resistance of the metal.

Electroplating: A process that uses the principle of electrolysis to coat the surface of a metal or other material with a layer of metal or alloy. This process, through the action of electrolysis, makes the surface of metal or other materials attached with a layer of metal film, so as to prevent metal oxidation (such as rust), improve wear resistance, electrical conductivity, reflective property, corrosion resistance and improve the appearance of the effect.

Spraying is a coating method by spraying gun or dish atomizer, with the help of pressure or centrifugal force, the paint is dispersed into uniform and fine droplets, which are applied on the surface of the coated object.

wire drawing is a surface treatment method that forms lines on the surface of the workpiece by grinding the product to play a decorative effect. Because the surface drawing treatment can reflect the texture of metal materials, it has been loved by more and more users and more and more widely used. This paper will discuss the surface wire-drawing treatment methods from the application of wire drawing, classification, processing methods, grinding products of wire drawing and related influencing factors of wire drawing

Sandblasting is a process for surface treatment of workpieces. The compressed air is used as the power to form a high-speed jet beam to spray the spray material (copper ore, quartz sand, emery, iron sand, sea sand) to the surface of the workpiece to be treated at high speed, so that the appearance or shape of the workpiece surface is changed.

Polishing refers to the use of mechanical, chemical or electrochemical action to reduce the surface roughness of the workpiece in order to obtain a bright, flat surface processing method. Is the use of polishing tools and abrasive particles or other polishing media to modify the surface of the workpiece.

大批量的生产

公司拥有100+CNC3轴、4轴和5轴机床,能够满足客户不同数量的和平需求。

Economical accuracy thanks to 3-axis CNC milling. For simple parts that still need precision, this is your first choice.

With a design in mind, 4-axis milling might be possible. Multilateral processing becomes easier.

How to Start Your Order

- Send your drawings

- Process discussion, quotatione

- Make a sample

- Volume produce

- Shipment &Payment

checkout

Promologo offers a wide range of mahjong packaging options, including classic mahjong soft cases,

packaging

Promologo offers a wide range of mahjong packaging options, including classic

您将得到

Promlogo has over 500 customized mahjong sets for you to choose from.You can also send us your own design requirement including the Edge Style, finish, font etc.

品质保证

We provide a full range of inspections to ensure that the mahjong tiles dimensions are accurate and that the mahjong patterns are clear, uniformly coloured and flawless.

定制材料

We provide a full range of inspections to ensure that the mahjong tiles dimensions are accurate and that the mahjong patterns are clear, uniformly coloured and flawless.

任意尺寸

We provide a full range of inspections to ensure that the mahjong tiles dimensions are accurate and that the mahjong patterns are clear, uniformly coloured and flawless.

快速反应

We provide a full range of inspections to ensure that the mahjong tiles dimensions are accurate and that the mahjong patterns are clear, uniformly coloured and flawless.

定制表面处理

We provide a full range of inspections to ensure that the mahjong tiles dimensions are accurate and that the mahjong patterns are clear, uniformly coloured and flawless.

不限制数量

We provide a full range of inspections to ensure that the mahjong tiles dimensions are accurate and that the mahjong patterns are clear, uniformly coloured and flawless.

Brand we cooperated with

Promlogo has over 500 customized mahjong sets for you to choose from.You can also send us your own design requirement including the Edge Style, finish, font etc.

Frequent Asked Questions

1.Is CNC milling easy?

The CNC machining process can be challenging to master, but it is certainly not out of reach. You should expect it to take more than 3 years of hard work to master, but it can take just a few hours of simple tutorials to create the basic parts.

2How is CNC milling different from normal milling?

There are significant differences between ordinary milling machine and CNC milling machine in operation mode, machining accuracy and range, production efficiency and automation degree. Ordinary milling machines need manual operation, CNC milling machines are operated by digital means to achieve automated production. Ordinary milling machine processing accuracy and range is limited, CNC milling machine can achieve high precision machining of various complex parts. In the future, the application of CNC milling machines will be more extensive.

3.What are the risks of CNC milling?

There are many risks in CNC milling process, including mechanical injury, electric shock hazard, noise and vibration, tool and cutting debris splash and so on.

1, mechanical injury : CNC milling machine in the operation process will rotate at high speed, if the operation is not skilled or accidentally put the hand into the machine, it may cause clamping, cuts and other mechanical injuries .

2, danger of electric shock : CNC machine tools usually need electric power to drive, if damaged wires or equipment failure to leak electricity, may cause electric shock accident .

3, noise and vibration : CNC machine tool operation will produce large noise and vibration, long-term exposure to this environment may cause hearing damage, and may cause fatigue and discomfort .

4, tool and cutting debris splash : CNC milling process will produce high-speed splashing cutting debris and tools, if improper protection measures or misoperation, may cause injury .

In order to ensure safety, operators should strictly follow safe operating procedures, use appropriate personal protective equipment, such as protective glasses, ear plugs, etc., and regularly check and maintain equipment to reduce these risks. In addition, for the dust and harmful gases that may be generated in CNC milling processing, corresponding protective measures should also be taken, such as wearing masks and ear mugs, and ensuring that the working environment is well ventilated to protect the health and safety of the operator .

4.How long does it take to learn CNC?

Like most skills, CNCmilling is a skill that is built through experience and trial and error. It can be learned and operated in a few hours.

Related Article About Mahjong

Promlogo has over 500 customized mahjong sets for you to choose from.You can also send us your own design requirement including the Edge Style, finish, font etc.

在此添加您的标题文本

Promologo offers a wide range of mahjong packaging options, including classic mahjong soft cases, delicate wooden gift boxes, durable plastic boxes and travel-friendly mahjotions, including classic mahjong soft cases, delicate wooden gift boxes, durable plastic boxes

Aug30.2014

在此添加您的标题文本

Promologo offers a wide range of mahjong packaging options, including classic mahjong soft cases, delicate wooden gift boxes, durable plastic boxes and travel-friendly mahjotions, including classic mahjong soft cases, delicate wooden gift boxes, durable plastic boxes

Aug30.2014

在此添加您的标题文本

Promologo offers a wide range of mahjong packaging options, including classic mahjong soft cases, delicate wooden gift boxes, durable plastic boxes and travel-friendly mahjotions, including classic mahjong soft cases, delicate wooden gift boxes, durable plastic boxes

Aug30.2014